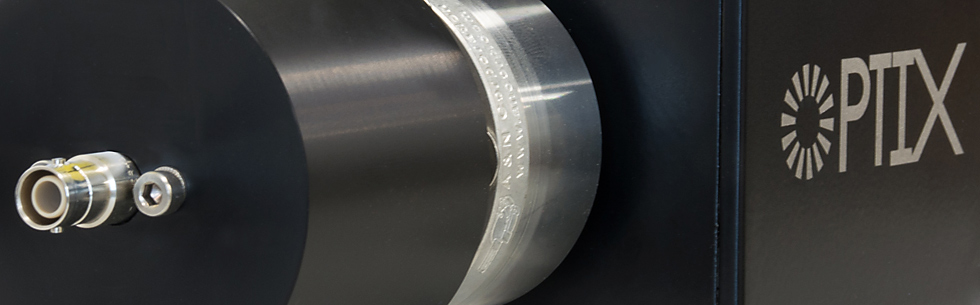

Optix

Optix is a multi-purpose instrument for rapid gas sensing in any vacuum environment, functioning through a wide range of operating pressures to cater for most industrial vacuum production processes without any requirement for a differential pumping system unless atmospheric sampling.

Separated from chemicals by an optical window, Optix uses a remote plasma spectroscopy concept which generates a small plasma within the sensor head. A built-in spectrometer analyzes the plasma, automatically interpreting the light spectrum to provide quantitative measurement of the presence and concentration of gas within the vacuum.

The Optix spectral information and sophisticated back-end software creates a range of uses for a wide range of applications, including contaminating processes involving hydrocarbons, solvents and long-chain polymers.

Small changes are made to the device in the case of sensing CVD and ALD type processes in order to prevent contamination of the plasma head. Sensing from atmosphere is also possible with a small roughing pump to bring the gases into the sensor.

Optix is very portable and easily switched between different vacuum systems or hand-carried in a small box to customer sites. It also offers an ultra-high sensitivity single gas option for dedicated leak detection.

Applications/Processes

• ALD

• CVD

• Etch

• Heat treatment

• Hipping

• Leak detection

• MOCVD

• OLED

• Plasma spraying

• Process gas analysis

• PVD

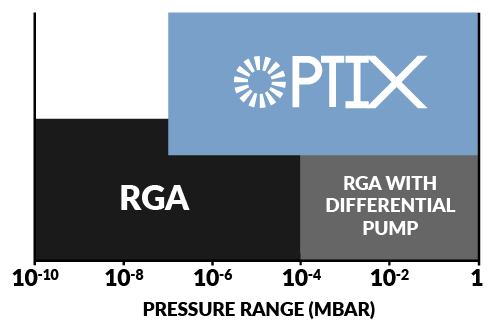

Pressure regime advantages

• Wide pressure range, operating directly at most process pressures

• No need for expensive/complex differential pumps

• No spurious readings from differential pump systems

• No filaments and low maintenance

• Chemically-tolerant with dedicated version for ALD and CVD processes

• Automatic calibration of total pressure reading

• Direct monitoring of the vacuum instantly register any changes (m/sec response)

• Significantly less expensive than RGA and differential pump combination

Interface

An advanced Windows user interface provides clear visualisation of the condition of the process and vacuum, and powerful tools for recording and referencing data enable easy identification of process problems.

Up to 20 gases can be monitored simultaneously, with process gas tracking that can be set up with trigger/alarm outputs.

A full, tuneable spectrum view (200-850nm) provides control of integration time for sensitivity adjustments, and automatic gas peak detection works from a gas auto identification database which can be adjusted to incorporate additional peaks of specific interest.

Software features

• Built-in spectrum database for atomic and molecular emission signatures

• Automatic spectrum interpretation

• Time plots for automatically or user defined species

• Customizable trigger set-up for end point detection or process control

• Comprehensive data recording and data referencing capability

• Vacuum quality tracker

• Leak detection mode

More information on the features included in the Optix software are detailed in the video presentation on Real time spectral plasma analysis software tools

Gallery

Downloads

Gencoa Optix flyer

Gencoa Optix flyer Optix for ALD processes

Optix for ALD processes Optix for Leak Detection

Optix for Leak Detection Optix for Vacuum Heat Treatment

Optix for Vacuum Heat Treatment Gencoa Optix presentation

Gencoa Optix presentation Monitoring the Outgassing of Powders Prior to Sintering and Hiping

Monitoring the Outgassing of Powders Prior to Sintering and Hiping Optix for chemical sensing

Optix for chemical sensing SVC Bulletin (Summer 2022): Automated analysis of vacuum processes using AI

SVC Bulletin (Summer 2022): Automated analysis of vacuum processes using AI EVC-15: Monitoring of volatile vacuum species using remote optical emission spectroscopy

EVC-15: Monitoring of volatile vacuum species using remote optical emission spectroscopy SVC TechCon 2019: Modelling and Analytical Stability Analysis of Feedback Controlled Reactive Sputter Processes

SVC TechCon 2019: Modelling and Analytical Stability Analysis of Feedback Controlled Reactive Sputter Processes Optix (STP file)

Optix (STP file) Optix dimensions

Optix dimensions Optix power supply dimensions

Optix power supply dimensions

Related Applications

Contact Gencoa

To contact Gencoa at our Liverpool headquarters, click for contact details.

For details of international representatives, refer to our list of worldwide contacts.