Hard coatings

Gencoa have been developing process and magnetrons for tool coating since the mid-1990's, and the wealth of experience amongst our staff enables Gencoa to provide an optimum solution for hard coating applications.

Products and services by Gencoa that are used in the area of hard coatings include:

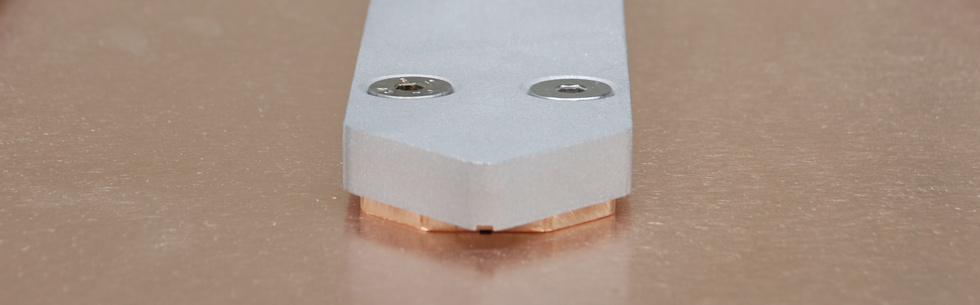

- GRS-V rotatable magnetrons with option VTR and Active Anodes

- High energy unbalanced planar magnetron cathodes (PP type)

- VT and VTR variable magnetrons

- Speedflo reactive gas process controller

- Optix vacuum gas monitor

- Complete chamber magnetic modelling to optimize ionization levels

- Process routines and on-site implementation

- Pumping and gas calculations for successful reactive processes

To deliver an optimized hard or decorative coating unit a wide variety of elements need to be carefully understood and designed correctly. There are two options: purchase a complete turn-key facility from an established manufacturer or purchase the key components and integrate in the correct way. If the component route is taken the process routines need to be implemented to create the balance of tool adhesion, hardness and toughness. Gencoa can provide and combine all elements of these components to ensure the highest chance of a successful solution.

A key element to a successful sputter-based hard coating process is the reactive gas control. The Speedflo unit provides a high speed gas control to optimize rates and enable the changing of the setpoints during the coating process. This provides a high degree of stability and a high rate process. Pre-programmed routines are available to be loaded into the Speedflo unit that can create the graded nature of the layer structure. The other essential element is to provide enough ionization for a dense coating structure without the need for too high a substrate bias (high bias leads to brittle coatings). Gencoa have experience of designing machine geometries that can create the right process environment. Without the required level of ionization, a successful layer structure will be hard to create.

The usual method of reactive gas feedback control is to collect a light signal from the plasma as the indication of the balance of metal to reactive gas, a method known as plasma emission monitoring (PEM). Gencoa have now developed the Speedflo unit to control a typical hard coating processes direct from the target voltage only. This highly desirable solution avoids the cost and inconvenience of fibre-optics located within or on the process chamber.

Related Products

- • Active anode

- • Compact cathode

- • Dual rectangular magnetron

- • GRS-C

- • GRS-M

- • GRS-S

- • GRS-V: Rotatable Magnetron

- • Linear ion source

- • Optix

- • Plasma treater

- • Single rectangular

- • Speedflo

Find us

Gencoa's main facility is situated in South Liverpool. Click for directions >