Single rectangular

Gencoa planar rectangular magnetrons combine low ownership cost, robust design and highly-optimized magnetics to produce a reliable product delivering high performance. Our rectangular magnetrons are in use in almost every type of industrial coating application including semiconductor, architectural glass and display coating.

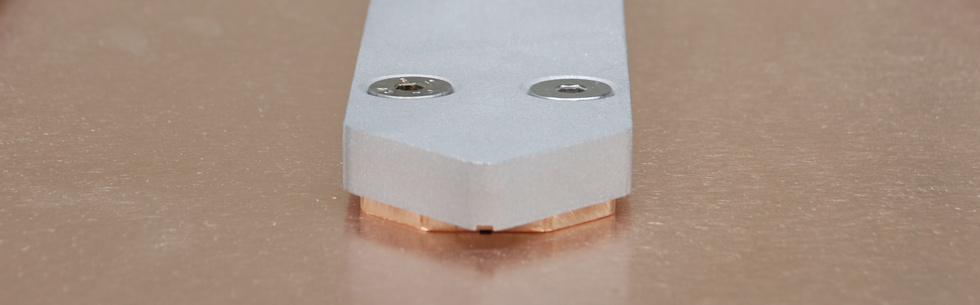

A unique design incorporating 'zero-height' anodes prevent short circuits during processes and reduce dust and defects in the coatings. All sources incorporate rear flange plate cooling as standard and additional anode water cooling is optional.

Depending on the application, Gencoa can configure individual cathodes to meet specific process requirements and limitations. An OEM proprietary magnetron design and manufacture service is also offered, and cathode CAD dimensional data can be downloaded in 2D and 3D formats using Gencoa's drawing generator (registration required).

Key features

- Robust with choice of optimized magnetics

- RF standard electrical insulation

- Two water inputs/outputs for enhanced flow and target cooling

- Zero-height anodes to prevent shorts and arcing

- Integral anodes with option of water cooling or zonal gas injection

Magnetics

High Yield (HY) range achieve 40% target utilization and are recommended for applications where increased machine up-time or reduced material costs are required.

Metallizer (MZ) range is designed for high-rate metallizing of webs, car parts and decorative applications. Using specially-designed thick profiled targets and high water flows, the MZ range can increase the machine up-time by 100%.

Vtech (VTER) range is dedicated to ion assisted deposition processes, where the degree of plasma impact on the growing film can be automatically varied by in-situ changing of the magnetic field.

Ferromagnetic (HS) and (Loop) sputtering options for up to 6mm Nickel and 2mm Iron by (HS) magnetics or custom magnetic arrangement to suit ferromagnetic materials in Gencoa (Loop) magnetics.

High Uniformity (HU) magnetics for optimised magnetic field uniformity for demanding applications. This is beyond Gencoa standard magnetic field scanning and QC and can provide magnetic field uniformities of better than 1% (TBC)

Gallery

Downloads

Gencoa rectangular magnetron flyer

Gencoa rectangular magnetron flyer Magnetic options for planar magnetrons

Magnetic options for planar magnetrons Rectangular target details

Rectangular target details Target power density

Target power density Water cooling options

Water cooling options

Related Applications

Upcoming Events

- 8-10 April 2026 - 5th Heat Treatment and HIP User Conference

- 14-16 April 2026 - Heat Treat Mexico

- 25-30 April 2026 - SVC Techcon

- 19-21 May 2026 - R2R Conference USA

- View full list >