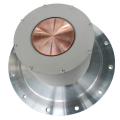

Circular FFE

Gencoa full face erosion (FFE) magnetics combine ultra-uniform films with clean target erosion by a scanning of the plasma over the target surface.

Two versions of the circular FFE are available, with a unique design for target diameters of 75mm-200mm (3" to 8") which includes options of internal and external mount, and is ideally suited to R&D and optics.

For larger substrates, Gencoa offer the circular FFE in target diameters of 250mm (10") and above, delivering superior uniformity control at low target-to-substrate separations – typically 50-70mm. This low target-to-substrate separation ensures a high rate of material transfer from the target to the substrate for rapid wafer metallizing.

Gencoa's range of FFE magnetrons overcome many of the traditional difficulties experienced when performing high-rate reactive deposition, such as nodule growth rates, whilst increasing the total target surface sputtering area.

High target use

Target use is high (>50% on a 6mm target), with a clean target even when reactive sputtering, and no redeposition areas on the target surface, fewer arcs and a lower number of coating defects. Target use of up to 70% can be achieved using the 6" circular FFE magnetron (FFE150).

Uniformity

A high rate of uniformity is achieved through motor driven dynamic plasma scanning in order to sputter the whole target surface, and maximum erosion at the outer edge of the target. There is no uniformity drift with target life.

The uniformity will vary with target-to-substrate separation. This can also be used to correct the uniformity as the target erodes and wafer size. The 12" circular FFE magnetron (FFE300) can deposit layers with 1-3% uniformity onto 200mm wafers.

Options

Gencoa circular FFE magnetrons are available from 3" to 18" OD targets, with a range of mechanical options available.

- Internal or External Mounting

- Tilting shaft mount

- Gas Injection

- RF Power Option

- Anode Cooling

- Choice of motor and controller

- Shutter (manual or automatic)

- Sputter Chimney

- Wall Mount Feedthrough

- Hidden Anode

Gallery

Downloads

Gencoa Circular FFE flyer

Gencoa Circular FFE flyer Circular FFE300 presentation

Circular FFE300 presentation FFE300 uniformity tuning

FFE300 uniformity tuning FFE75 circular magnetron

FFE75 circular magnetron Gencoa FFE430

Gencoa FFE430 SVC TechCon 2019: Conformal Coatings Deposited on Microstructured Substrates using HIPIMS and a Full Face Erosion cathode

SVC TechCon 2019: Conformal Coatings Deposited on Microstructured Substrates using HIPIMS and a Full Face Erosion cathode SVC Techcon 2022: Process Benefits of a Clean Sputter Target by Dynamic Plasma Movement on Circular Planar Magnetrons

SVC Techcon 2022: Process Benefits of a Clean Sputter Target by Dynamic Plasma Movement on Circular Planar Magnetrons Magnetic options for planar magnetrons

Magnetic options for planar magnetrons

Related Applications

Product brochure

Download a PDF copy of Gencoa's latest product brochure.